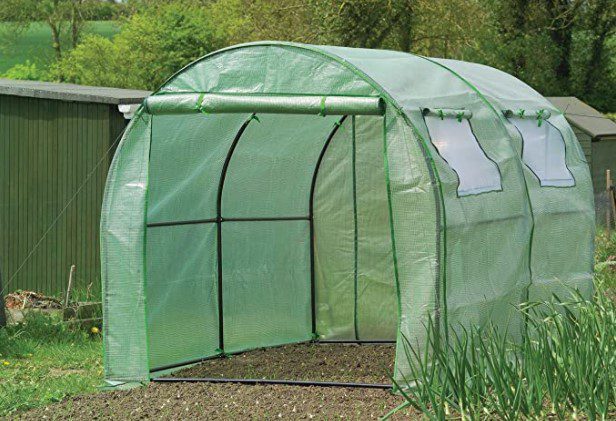

Polytunnels

At around half the price of glasshouses, polytunnels offer numerous benefits to growers. Used extensively by nurseries and growers to develop their plants and crops in a controlled, uniform way, today’s polytunnels are higher and wider than the single-span units supplied 30 years ago.

The range now extends from portable temporary units to single- and double-span to a full range of multi-span/ multilink constructions. In nearly all instances planning permission is required for this type of building.

The width of polytunnels ranges from 3m to 9m. Prices start at around £500 for a smaller structure of 3m by 7m, and you can expect to pay around £8,000 per bay for a multi-span, depending on its specification.

At National Polytunnels, sales manager Gary Summerfield says multi-span tunnels are selling extremely well. “More and more multi-span are now being supplied because they provide an improved working area and create more airflow,” he says.

Basic polytunnel structures consist of a stanchion/hoop assembly, ridge, and bracing, providing a sound framework for the cladding.

Multi-span usually includes valley gutters and side gutters. During the construction process, polytunnels can be secured by footplates bolted into concrete or foundation tubes.

The tubes should be set absolutely vertical in concrete, and for larger projects, a 20Nm/GEN3 concrete mix is recommended.

Doors can be hinged, single or double sliding, depending on the type and size of the tunnel.

Ventilation is vital for nursery stock and bedding-plant hardiness, together with disease control. The options include side ventilation, roll-up side vents, lift-up side vents, and gable-end vents through automated units operated by an electronic weather station.

Playhouse, a division of Fordingbridge, uses large-diameter high-tensile steel tubes for the framework of its range of tunnels. This provides a higher bending resistance to wind and snow loads.

When housed on more exposed sites, it is advisable to screen the polytunnel to help provide protection and extend the life of the polythene.

As a rule, single-span tunnels can be easily built as no specialist equipment is required, and work can be carried out from ground level.

But twin and multi-span units require far more safety measures, including the use of nets on either side of the valley gutter to prevent anyone from falling to the ground.

For this reason, it is necessary to carry out a risk assessment and have work carried out by professionals. The nets must be constructed to comply with BS EN 1263-1 and installed by personnel trained to BS EN 1 263-2 standard.

Range of cladding materials

The cladding range includes a standard clear Visqueen film of 72Og. This is recommended for most salad crops and bedding plants as it has a light transmission of 89 percent.

For nursery stock and shade-loving crops, white is often preferred as it has a light transmission of 70 percent.

Advanced Visqueen film of 720g is also available and has good anti-condensate properties. Further benefits include allowing the sun’s rays in a while, preventing heat from escaping, making this film good for early-yield crops.

Netting sheets can also be used and are manufactured from monofilament or tape, which is then sewn to size.

For hardy nursery stock and ornamentals, 800g Luminance is highly effective. This is due to its ability to reduce the proportion of shortwave infrared light, which lessens scorching and reduces maximum temperatures in hot weather.

Retail areas are often created from polytunnels and, In this instance, are usually covered with nicotarp. Woven polythene generally in a green-and-white striped pattern.

For storage buildings and mushroom houses, a green-and-white co-extruded film can be used, as layers of insulation can be fitted between the sheets, which gives important savings on energy costs.

Growing with single-span units

Kirton Farm Nurseries, based in Hampshire, uses net-sided polytunnels to produce its herbaceous perennials and herbs, which are sold to multiples, garden centers, growers, and landscapers.

More than 30 polytunnels. which are 7.2m wide and more than 30m long are used to offer protection from too much rain for the 600,000 plantlets produced each year on sub-irrigated, capillary sandbeds.

Some tunnels are more than 20 years old, but more recent purchases include a McGregor polytunnel, which the nursery staff erected themselves on site.

Production manager Richard Clifton says: “The polytunnel sides are rolled up constantly as the tunnels are used for winter protection.

We are trying to keep the plants hardy but want to offer them rain protection.

“We require as much air as possible blowing through the panels – if plants were totally enclosed, there could be huge problems with diseases.”

GREEN TUNNELS

Given that many people object to the visual impact of some polytunnels, BPI Visqueen has developed several subtle green-colored films.

Polytunnels have had a significant impact on the UK fruit-growing industry by extending the growing season. This has led to a decrement in the amount of soft fruit imported into the UK and reduced its carbon footprint.

A further benefit is that tunnels have also eliminated most wet-weather diseases, helping to reduce pesticide use.

Amazon Offer of Polytunnel