Discover the top-rated best welding boots for maximum safety, comfort & durability. Explore our expertly curated selection and find the perfect pair for all your welding needs. Step into confidence today!

Welding is a profession that requires a lot of skill, knowledge, and experience. Welders use high temperatures to melt and join metal parts, making them dangerous.

One of the most important things to consider when welding is safety. And the first line of defense for a welder’s safety is their protective gear, including welding boots.

This article will discuss the factors to consider when choosing the best welding boots, the different types of welding boots, reviews of the best in the market, and frequently asked questions about welding boots.

Factors to Consider When Choosing Welding Boots

When choosing welding boots, there are several factors that you need to consider, such as safety standards, durability, comfort and support, type of welding, and budget.

Safety Standards

Safety should always be the top priority when working with welding equipment. Therefore, it is essential to choose welding boots that meet safety standards. The American Society for Testing and Materials (ASTM) sets the safety standards for welding boots.

The most common ASTM standard for welding boots is F2413-18. It covers several safety aspects, such as impact resistance, compression resistance, metatarsal protection, and electrical hazard resistance.

Make sure that the welding boots you choose meet the required ASTM standards.

Durability

Welding boots should be durable enough to withstand the harsh conditions of welding. Look for boots made of high-quality materials such as leather, which is durable and can resist heat and sparks. Welding boots should also have a sturdy sole that can resist punctures and slips.

Comfort and Support

Welding is a physically demanding job requiring much standing and walking. Therefore, it is essential to choose welding boots that offer comfort and support. Look for boots with cushioned insoles, padded collars, and ankle support. The boots should also fit well and provide enough room for your toes.

Type of Welding

The type of welding you do will also affect the type of welding boots you need. If you are doing MIG or TIG welding, you will need boots with high heat resistance. If you are welding a stick, you will need boots with good puncture resistance. Choose welding boots that are suitable for the type of welding you do.

Budget

Welding boots come in different price ranges. You don’t have to break the bank to get a good pair of welding boots. However, don’t compromise on safety and quality to save a few bucks. Choose welding boots within your budget but still meet the required safety standards.

Types of Welding Boots

There are different welding boots, each designed to meet specific safety requirements.

Steel-Toed Boots

Steel-toed boots are the most common type of welding boots. They have a steel cap in the toe area that protects against impact and compression. They are also puncture-resistant and have a heat-resistant sole.

Composite-Toed Boots

Composite-toed boots are similar to steel-toed boots but have a composite material in the toe area instead of steel. The composite material is lighter than steel and does not conduct heat or electricity, making them a good option for electric welding.

Metatarsal Guard Boots

Metatarsal guard boots have extra protection for the metatarsal bones in the foot. They have a shield that covers the laces and the tongue of the boots. They are ideal for welding situations with a risk of falling objects.

Heat-Resistant Boots

Heat-resistant boots are designed to withstand high temperatures. They are ideal for welding situations with a lot of heat, such as MIG and TIG welding. They are usually made of leather or other heat-resistant materials and have a heat-resistant sole that can withstand the heat generated by the welding process.

Reviews of the Best Welding Boots

To help you find the best welding boots, we have reviewed three of the best welding boots available in the market.

1. Timberland PRO Men’s 6″ Pit Boss Steel Toe

The Timberland PRO Men’s 6″ Pit Boss Steel Toe is popular for welders. These boots meet ASTM safety standards and protect against impact, compression, and electrical hazards. They are made of high-quality leather and have slip-resistant soles.

The boots also have a removable insole that provides extra cushioning and support. The only downside is that they are a bit heavy, which can be uncomfortable if you have to wear them for long hours.

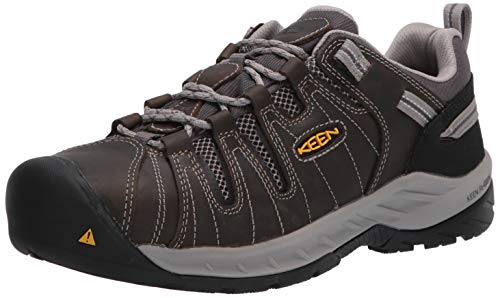

2. KEEN Utility Men’s Flint Low Steel Toe Work Shoe

The KEEN Utility Men’s Flint Low Steel Toe Work Shoe is another excellent option for welding boots. These boots are made of a combination of leather and mesh, which makes them lightweight and breathable.

They have a steel toe cap that protects against impact and compression. The boots also have a slip-resistant sole and a removable insole for added comfort. The only downside is that they are not suitable for high-heat welding.

3. Dr. Martens Men’s Ironbridge Steel Toe Heavy Industry Boots

The Dr. Martens Men’s Ironbridge Steel Toe Heavy Industry Boots are a durable and comfortable option for welding boots. These boots are full-grain leather and have a steel toe cap that protects against impact and compression.

They also have a slip-resistant sole and a padded collar for added comfort. The boots are suitable for high-heat welding and meet ASTM safety standards. The only downside is that they can be stiff at first, but they will break in over time.

FAQs about Welding Boots

Here are some frequently asked questions about welding boots.

Can I wear regular work boots for welding?

No, regular work boots are not suitable for welding. Welding boots are designed to meet specific safety requirements, such as heat resistance, impact resistance, and electrical hazard resistance. Regular work boots may not provide adequate protection for welding.

How do I know if my welding boots are safe?

Welding boots should meet ASTM safety standards, such as F2413-18. Look for the ASTM label on the boots or check with the manufacturer to ensure that the boots meet the required safety standards.

How often should I replace my welding boots?

It is recommended to replace your welding boots every six months to a year, depending on how often you wear them and the conditions in which you use them. Inspect your boots regularly for signs of wear and tear, such as cracks, holes, or worn-out soles.

What boots are best for welding?

The best boots for welding are those that provide safety features such as steel toe caps, heat-resistant material, slip-resistant outsoles, and electrical hazard protection. Look for boots designed specifically for welding work.

What to look for in welding boots?

When selecting welding boots, look for safety features such as steel toe caps, metatarsal guards, electrical hazard protection, slip-resistant outsoles, and heat-resistant material. Also, consider the comfort level, durability, welding type, and budget.

Are steel-toe boots suitable for welding?

Yes, steel toe boots are excellent for welding as they provide adequate protection against heavy tools, sharp objects, and hot metal.

What are the best Timberland boots for welding?

The Timberland PRO Men’s 6″ Pit Boss Steel Toe is a popular choice for welding boots from Timberland.

Should welders wear steel-toe boots?

Yes, welders should wear steel toe boots to protect their feet from heavy objects, sharp tools, and hot metal.

What type of safety shoes should a welder wear on welding?

A welder should wear safety shoes that meet ASTM safety standards, such as F2413-18. Look for shoes that provide protection against impact, compression, electrical hazards, and heat.

Can you weld in steel toe boots?

Yes, you can weld in steel toe boots as they are designed to provide adequate protection against the hazards of welding work.

What is a good boot for welding?

A good boot for welding provides safety features such as steel toe caps, metatarsal guards, slip-resistant outsoles, and heat-resistant material. Some popular brands for welding boots include Iron Age, Rockrooster, and Caterpillar.

Do I need a steel toe for welding?

Yes, it’s recommended to wear steel toe boots while welding as they provide adequate protection against heavy tools, sharp objects, and hot metal.

What is the purpose of welding boots?

The purpose of welding boots is to protect the feet of the welder from hazards such as sharp objects, heavy tools, hot metal, and electrical hazards.

What types of footwear are recommended for welders?

Steel toe boots, composite toe boots, metatarsal guard boots, and heat-resistant boots are recommended for welders.

What boots are good for welders?

Good boots for welders provide safety features such as steel toe caps, metatarsal guards, slip-resistant outsoles, and heat-resistant material. Some popular brands for welding boots include Iron Age, Rockrooster, and Caterpillar.

What are the best work boots for welders?

The best work boots for welders provide safety features such as steel toe caps, metatarsal guards, slip-resistant outsoles, and heat-resistant material. Some popular brands for welding boots include Iron Age, Rockrooster, and Caterpillar.

What kind of boots should a welder wear?

A welder should wear boots that provide safety features such as steel toe caps, metatarsal guards, slip-resistant outsoles, and heat-resistant material.

What is the best steel toe work boot brand?

Some of the best steel toe work boot brands include Iron Age, Caterpillar, Red Wing, and Wolverine.

Final Word

Finding the best welding boots is critical to ensuring your safety and comfort while working with welding machines and heavy tools. Welding boots come in different types and styles, such as laced boots, pull-on boots, cowboy boots, and waterproof boots, with safety features such as steel toe caps, metatarsal guards, electrical hazard protection, and slip-resistant outsoles.

Some of the best steel-toe boots on the market include Iron Age welding boots, Rockrooster welding boots, and Caterpillar Men’s welding boots.

When selecting welding boots, consider factors such as safety standards, durability, comfort, type of welding, and budget. Look for boots with built-in met guards, heat-resistant materials, and waterproof membranes to protect your feet from molten metal spatter, fire hazards, and wet conditions.

In addition to the safety features, it’s also important to consider the level of comfort provided by the welding boots. Look for boots with padded footbeds, shock-absorbing midsoles, and flexible synthetic soles to prevent blisters, foot pain, and fatigue during long periods of work.

Before making a purchase, read customer reviews, and consider the reputation of the brand. Make sure to get the right size and fit for your feet and personal preference. Also, it’s crucial to replace your welding boots regularly to ensure that they still provide adequate protection.

Welding boots are just one piece of personal protective equipment that you should wear while working in a welding shop. Other PPE includes safety glasses, welding helmets, gloves, and fire-resistant clothing.

By investing in proper welding boots and other PPE, you can protect yourself from serious injury and work safely for extended periods.

Lastly, it’s important to note that the cost of welding boots should not be the sole determining factor in your purchasing decision. While you can find affordable options, it’s essential to ensure that the boots offer the necessary safety features and durability to protect your feet from piercing hazards, heavy objects, and electrical hazards. Remember, your safety is the top priority.

In Conclusion

finding the right welding boots for your needs is essential to ensure your safety, comfort, and productivity on the job. Look for boots with the necessary safety features, durability, and comfort to protect your feet from sharp objects, hot metal, and electrical hazards.

Always invest in high-quality personal protective equipment and replace your welding boots regularly to ensure they still provide proper protection.

With the right welding boots, you can work safely and confidently for extended periods, reducing the risk of injury and improving your work performance.

Last update on 2024-11-21 / Affiliate links / Images from Amazon Product Advertising API